Find Out More – Instrumentation

Course: Instrumentation

Trade Title: Instrumentation

OFO No: 672105

Accreditation Body: Quality Council for Trades and Occupations

What is an Instrument Mechanician?

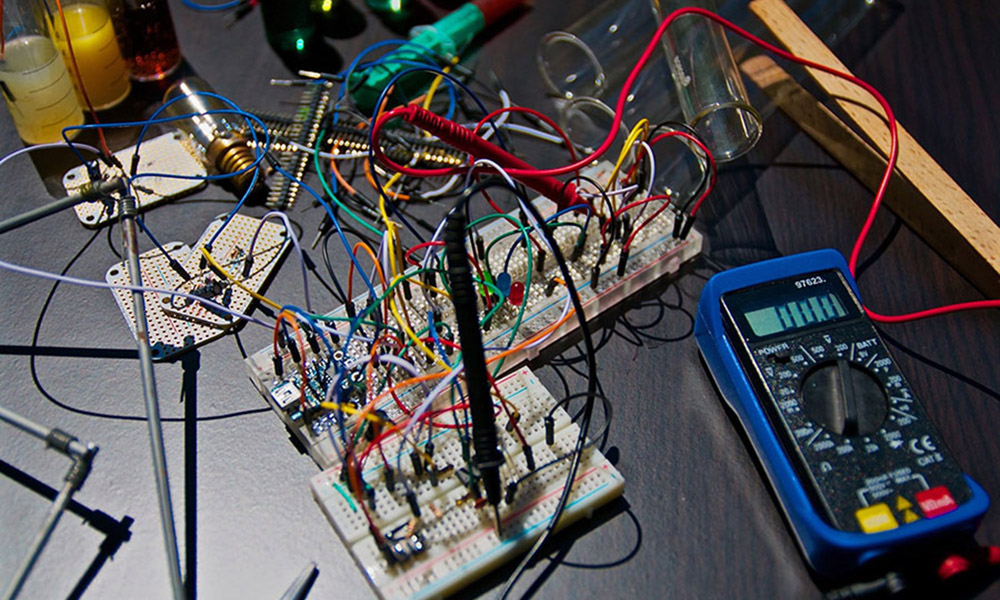

An instrument mechanician manufactures and repairs instruments and recalibrates old instruments. The instrument mechanician plays a vital role in ensuring that automatic processes and plant systems operate correctly and efficiently. The control of nearly all manufacturing processes depends on instruments that may be electrical, mechanical or hydraulic, which are responsible for measuring the pressure, temperature, position, level, mass or flow of solids, fluids and gases. Should the plant processes not operate according to specifications, the instrument mechanician diagnoses the fault and carry out repairs as quickly as possible.

What does an instrument mechanician do?

- Installations

- Repairs

- Maintenance on plant instruments.

- Instrument calibrations

- Testing and inspections on sensors and transmitters.

Personal qualities required:

- Instrument mechanicians must be mathematically and scientifically inclined.

- Accuracy, good eye-hand co-ordination and patience are also important qualities.

- They must also be practical and have abstract reasoning abilities.

Instrumentation Phase 1

This course counts towards a credited Instrumentation Qualification which consists of both Theory and Practical Workplace Training. This online part of the course covers the Theory only.

The courses are accredited by the Quality Council for Trades and Occupations (QCTO) of South Africa.

Instrumentation Phase 2

This course counts towards a credited Instrumentation Qualification which consists of both Theory and Practical Workplace Training. This online part of the course covers the Theory only.

The courses are accredited by the Quality Council for Trades and Occupations (QCTO) of South Africa.